Ultrathin and small-diameter glass molded lens

Pursue Thinness and Smallness

-

-

Glass molded lenses are made by heating the glass material at an high temperature and pressing it with an elaborate mold made in nanometer units. Although the production efficiency is high, it is molded in a thin-walled shape. It can sometimes crack and requires an advanced manufacturing process.

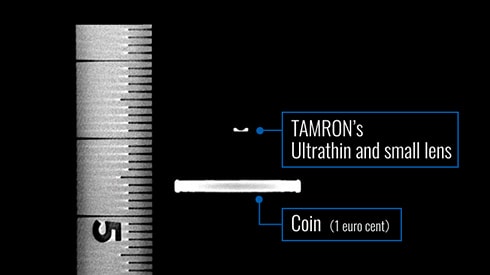

Tamron has realized an ultra-thin, small-diameter aspherical glass molded lens with a thickness of 0.1 mm, which is equivalent to copy paper. It can be expected to be used in optical systems such as wearable devices, robot eyes, and minimally invasive surgical cameras.

Tamron is evolving its lens processing technology in order to create lenses that can meet the ever-increasing demands for smaller equipment and higher resolution.

- Technology by glass molding technique that realizes high-precision shape processing and mass production at the same time

- Achieved the same 0.1mm thickness as copier paper

- Achieved a small-diameter lens processing technology and coating technology for small surface as well

- Adding an aspherical lens shape, realize a higher resolution lens with downsizing

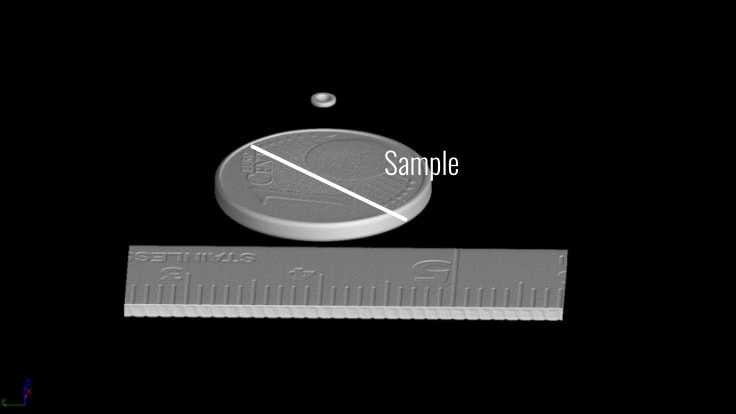

Achieves thickness of 0.1 mm (CT scan image)

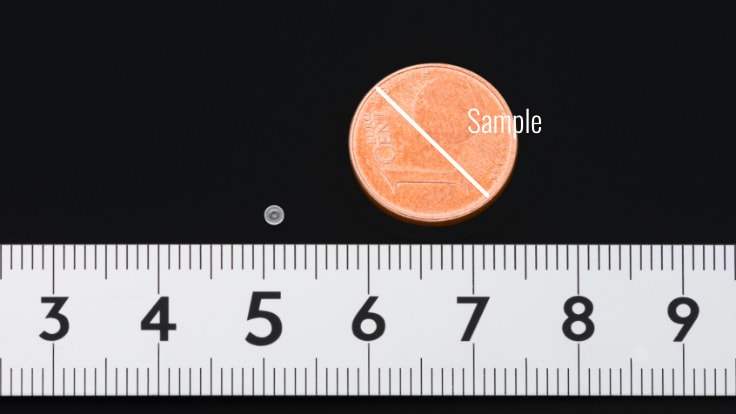

Small-diameter of Φ2.0 mm or less(CT scan image)

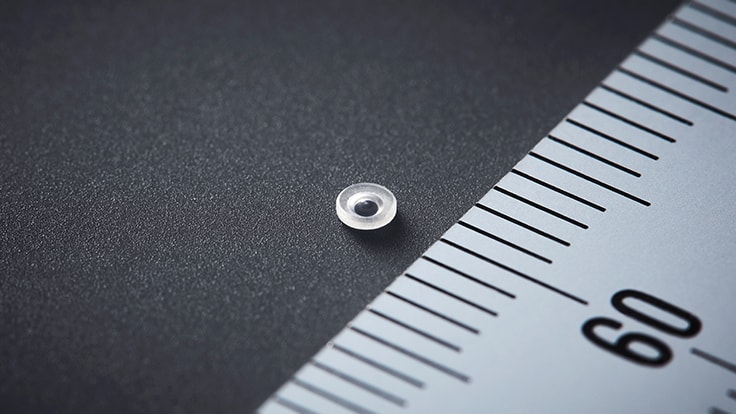

Small-diameter of Φ2.0 mm or less

Lens processing technology

lens

20230215010312