Exploring New Business Segments with Long-wave IR Optics

“Contributing to economy, society, and environment through product offerings created under a philosophy of Eyes for Industry” as remarked in Tamron’s CSR statement, ‘Eyes for Industry’ represents a corporate vision that is not confined to a general framework of cameras nor to a visual bandwidth human eyes. Tamron, being at the forefront in the security/surveillance business segment, has established a solid ground in the Near-IR (IR) lens solutions, extending the imaging arena beyond the visible wavelengths range. Essentially it is a natural move to expand the product portfolio toward the Long-wave IR arena in conformity with the company’s slogan. With a goal of assuming a leadership role in the segment in mind, Tamron is determined to take a proactive stance to offer discernibly higher image quality and better handling ease, making full use of proprietary technology and know-how that have been accumulated over the course of years. Bringing user benefits that would parallel those made available to products in the visible arena is the fundamental philosophy when building the product portfolio. To address various requirements in the Long-wave IR region is positioned as one of the segments for further technology development at Tamron going forward.

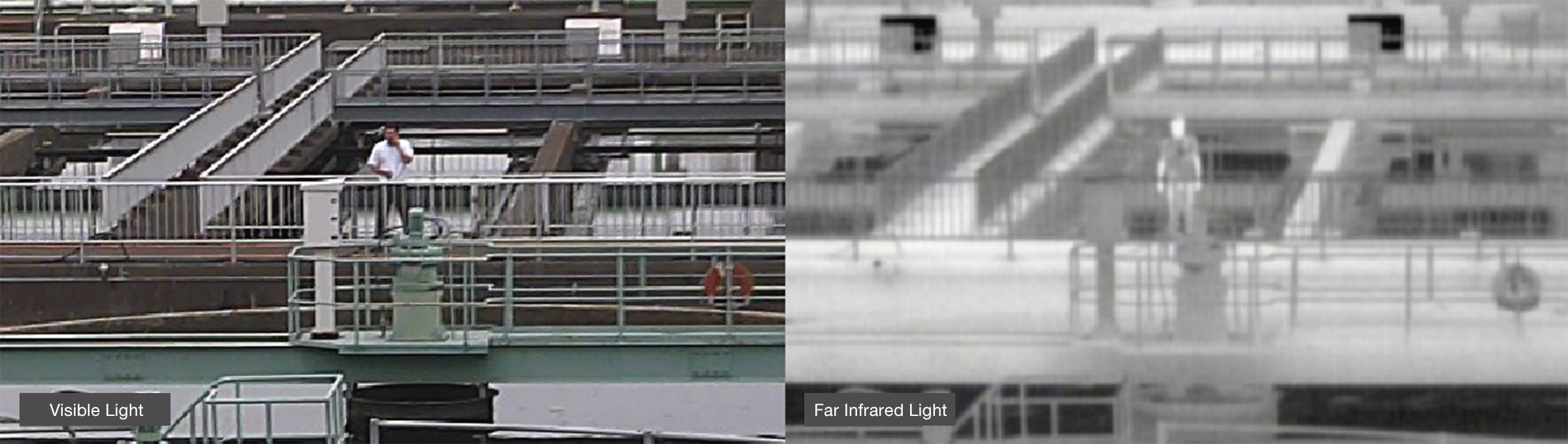

Images Only Long-wave IR Optics Can Deliver

Light being interpreted as a flux of electromagnetic waves, a wavelength between 380 to 780 nanometers are typically defined as the visible spectrum for human eyes. The bandwidth captured by a Long-wave IR cameras ranges from 8 to 14 micron (from 8000 to 14,000 nanometers), which inherently correlates to thermal irradiation. The principle attribute of a Long-wave IR camera is a detection of the heat emitted by an object and visualization of the thermal gradient. Notable applications include various crucial circumstances such as intrusion detection in pitch-dark areas, or detection of human beings in a smoke-filled environment under fire.

High Quality with Distinctive Cost Efficiency

Glass materials for visible spectrum block Long-wave IR and are not suitable for optics for that application. While Germanium is the most preferred material due to its high transmissivity in the Long-wave IR bandwidth, its cost and vulnerability for cost fluctuation often present problems in commercialization. A chemically compounded material such Chalcogenide, thus comes into play that could substitute for the Germanium in certain conditions in order to reduce the cost. Unlike Germanium, Chalcogenide can be shaped in form by means of molding process, a proprietary high-precision process technology on hand at Tamron. Through a close collaboration between design, process technology and production experts, an optimal selection and combination of the optical materials is identified to deliver a most cost-effective solution to users.

Quality Assurance for a Long-wave IR Lens without Compromise

A Long-wave IR lens by virtue of its inherent wavelength range beyond the visible spectrum requires a specific array of equipment both for assembly and inspection that are totally different from those tailored to the conventional visible range. Naturally, such equipment needs to be custom designed for production of Long-wave IR optics. Because of the fundamental difference in the wavelength range, Long-wave IR specific MTF (Modulation Transfer Function) tester is developed to ensure build quality of a lens unit in terms of decenter, tilt, air gap and the like when assembled. Although Long-wave IR detectors inherently come with lower resolutions (e.g. QVGA or VGA for the most part), which require less critical alignment in optical elements compared to visible lenses, the same level of process control is applied at Tamron to those Long-wave IR optics.

Long-wave IR Lenses Only Tamron Delivers

For surveillance applications, when an object is detected in a wider field of view, further details can be captured by zooming in to the object of interest, possibly enabling recognition of the same. Evidently, a zoom lens that covers both wide and narrow fields provides an efficient solution with a single lens unit. Tamron, in addition to the highly accredited technology for visible-wavelength zoom lenses, recently introduced an epoch-making Long-wave IR Zoom lens. Due to the property of the lens materials employed, a Long-wave IR lens is susceptible to changes in ambient temperatures coupled with the heat emitted from the detector itself, causing a focus shift. Athermalization is mandated for critical imaging for this reason. Tamron employed an Active Athermalization function on the zoom lens, which optimizes the cam curve tracking mechanism relative to the temperature to obtain the best image quality across the entire field positions without defocusing blur. This is another core technology developed in the visible domain transferred to Long-wave IR.

Building a Path to the Future

Including the first-in-the-world embedding of an optical VC (Vibration Compensation), a wealth of proprietary know-hows have been employed in the design and manufacturing of a Long-wave IR Zoom lens. The adoption of an industry-standard screw mount and a general-use communication protocol for the lens control assures users an easy lens installation. Making future technologies available and friendly by employing state-of-the-art and proprietary technologies is the Tamron way to build a path to the future; the Long-wave IR lens technology is one of Tamron challenges to realize this vision.